HENGYE MACHINERY CO.,LTD OF DONGGUAN CITY

Since 1991, we have been focusing on inventing and manufacturing quilting equipment. We Provide Customers With Professional And Excellent Mattress & Home textiles Intelligent Manufacturing Solutions.

Since 1991, we have been focusing on inventing and manufacturing quilting equipment. We Provide Customers With Professional And Excellent Mattress & Home textiles Intelligent Manufacturing Solutions.

+86-769-22264807

+86-13316667446

Product Center

Home Textiles | Mattress

Quilting Series

Mattress Edge

Sewing Series

Mattress

Packing Series

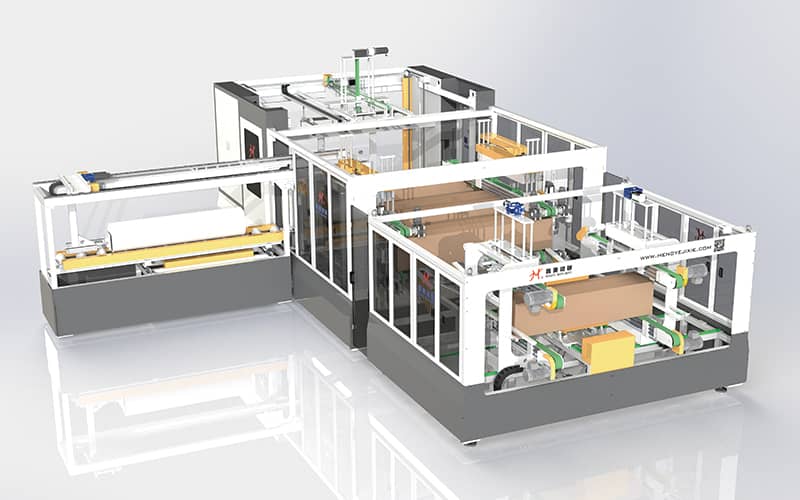

Mattress Smart

Production Iine Customiztion

HY-W-SJS-3S / 3S(Y)

Ultrahigh Speed Computerized Chain Stitch Multi-needle Quilting Machine

HY-W-BSJгҖҗBorder QuiltingгҖ‘

Computerized Chain Stitch Multi-needle Quilting Machine

[ C Series ]

Computerized Lock Stitch Multi-needle Quilting Machine

HY-DZ-2L2T

Computerized Double-beam Double-head Single Needle Quilting Machine

HY-FQ-2

Four Sides Hemming And Cutting Machine

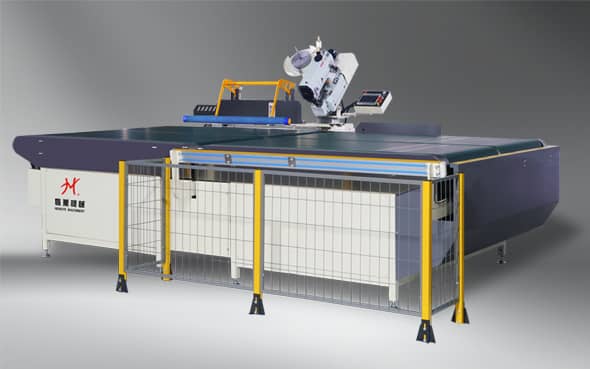

HY-QG-6 / 6 L / 6B

Computerized Panel Cutter Machine

HY-D-1

Automatic Stacking Machine

HY-W-SJS-3 / 3(Y)

Computerized Chain Stitch Multi-needle Quilting Machine

HY-TE-5B

Automatic Tape Edge Machine

HY-TE-4B

Automatic Tape Edge Machine

HY-ZX-1

Mattress Automatic Packing Machine

HY-DM-1

Automatic Palletizer Machine

ABOUT HENGYE

"With perseverance, do permanent industry"! Since 1991, we have been forging ahead and innovating. Domestic needle quilting machine, the first computer was born in dongguan production base, our decades, we always focus on computer automatic sewing equipment (multi needle quilting machine, single needle quilting machine), computer automatic cutting equipment, automatic seam cut production system of research and development, production, sales and related services, determined to "provide customers with professional, excellent quilting solution".

"Smart Made in China, serve the world"! For decades, the products sell well all over the world. In the domestic market, it has always been the representative of the largest holding quantity. Its products serve all provinces, cities and autonomous regions in China, and it has after-sales services in Beijing, Shandong, Jiangsu, Zhejiang, Sichuan, Henan, Jiangxi, Foshan, Guangdong and other places. Foreign markets, Southeast Asia, the Middle East, Europe, Africa, America, Oceania, have left our magnificent figure, Italy, Spain, Turkey, India, Malaysia, Indonesia, Argentina, Dominica, Russia, South Korea and other places with service outlets. Excellent enterprise, excellent brand, excellent team, excellent products, excellent service, promote Hengye to better "serve the world".

"Own production base, advanced quality management system, to provide strong support for excellent service". Dongguan production base with independent property rights covers an area of 10,000 square meters, self-built factory buildings of 15,000 square meters, with advanced and complete high-precision processing equipment, testing equipment, test equipment. We have ISO9001:2000 quality management system certification, and our products have passed CE certification. We also have a large number of R&D personnel with rich practical experience and strong innovation ability, and a dedicated, pragmatic and powerful staff team to escort our excellent products.

"Layout industrial chain, break through service limitations"Combined with "Foshan Zhonglian Machinery Technology" , to achieve group operation and service, from raw materials to finished mattresses warehousing a full set of intelligent production equipment and process solutions, we can provide full range of services, to provide customers with professional, excellent mattresses intelligent manufacturing solutions.

Quality first, customer first, considerate service, continuous improvement has always been the goal of Hengye Machinery. We have thick precipitation, strong innovation ability, and the pursuit of "creating greater value for global customers".

DEVELOPMENT HISTORY

PRESS CENTET